Plastic handles in the injection moulding process with many years of experience

The team of Jäger-Plastik produces plastic handles in the injection moulding process. The manufacturing already begins in the development. From the creation of the design to the production of the final product a continuous process. The ongoing quality control is indispensable in order to ensure a maximum of quality.

Among our strenghts is the product innovation. One of the most importants elements of a cooling bag (insulating carrier bag) is the handle. For this reason, with us manufacturers find different forms and sizes of plastic handles. One category includes the DTI / ISO – twin handle (oval). Further categories are, for example, the CLIP / ISO – twin handles (oval), POG / Oval – twin handles and the practical trapez – twin handles. These are design-technically mature products that all are produced with good quality materials in the plastic injection moulding process. The experiences speak for themselves.

If you are a manufacturer of cooling or thermo bags for supermarkets and department stores, please feel free to contact our product developer. We can realise almost all specifications and customers‘ requirements contemporarily and economically.

-

Recycling material (3)

-

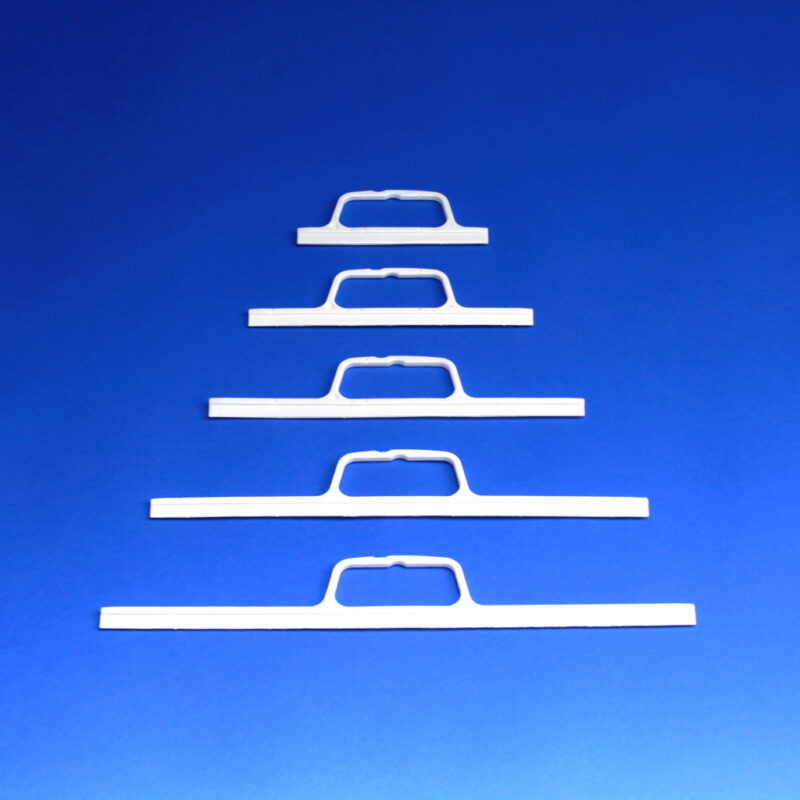

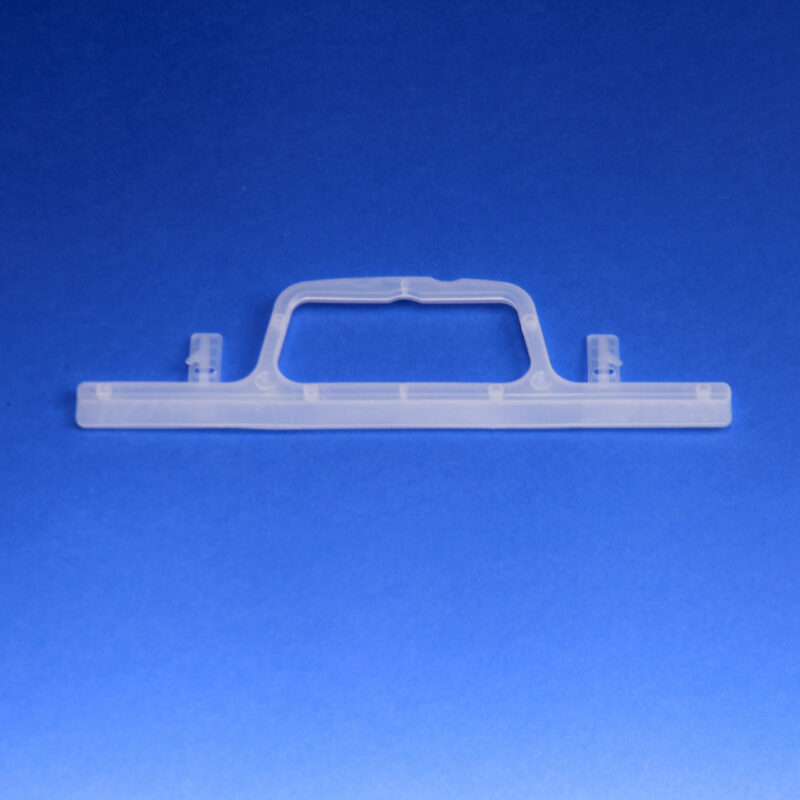

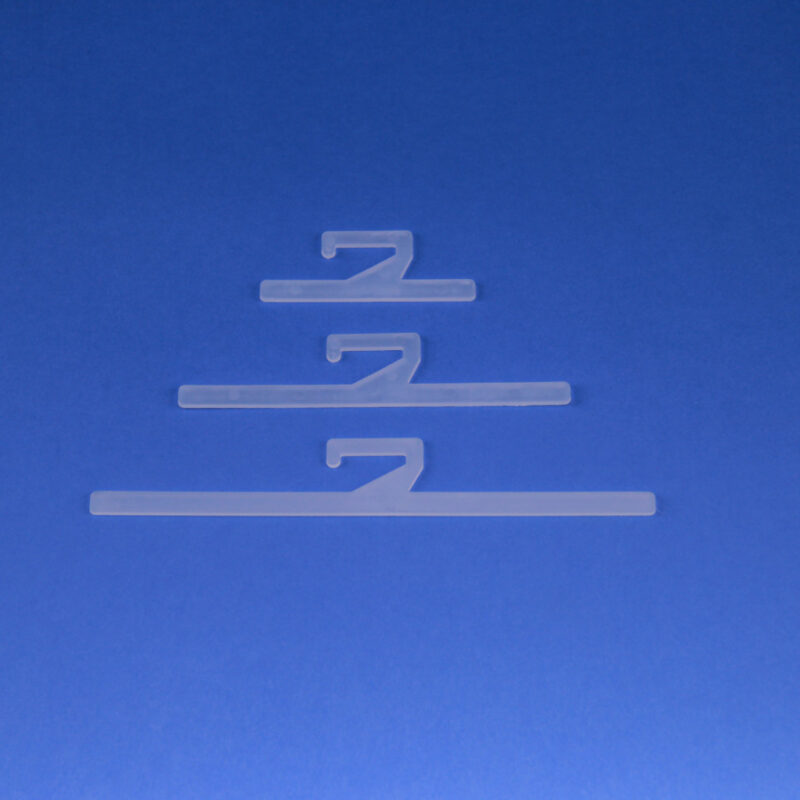

Twin handles (5)

-

Round bracket handles (2)

-

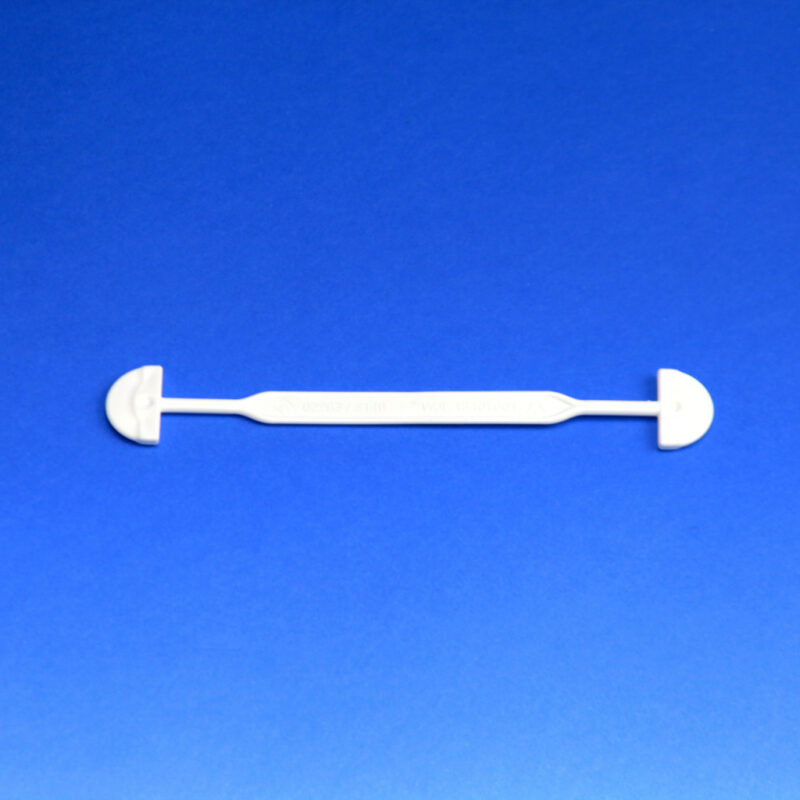

Single hook racks (1)

-

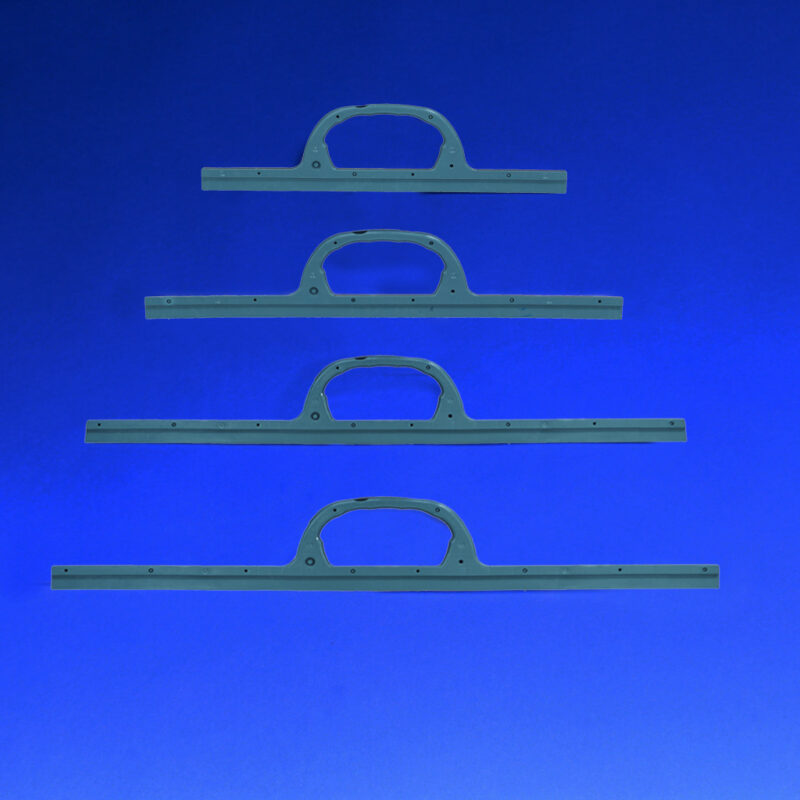

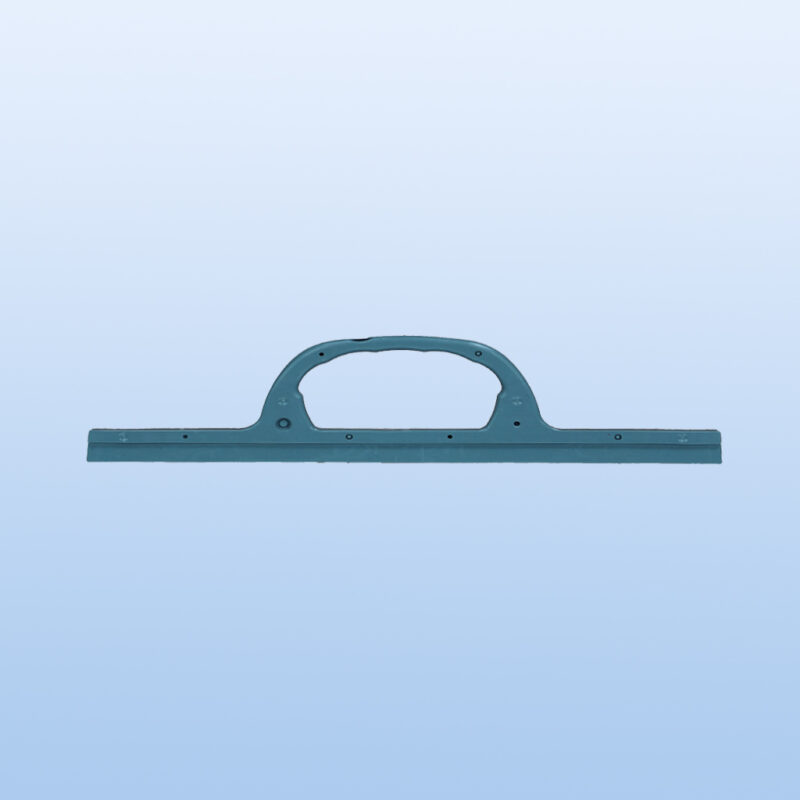

CLIP / ISO – twin handles – oval PCR

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

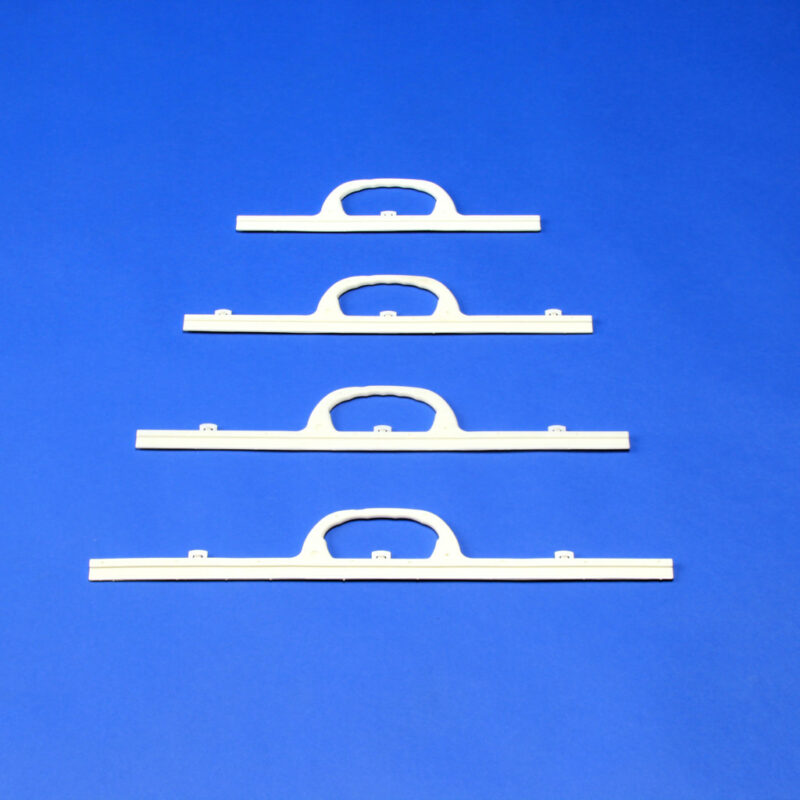

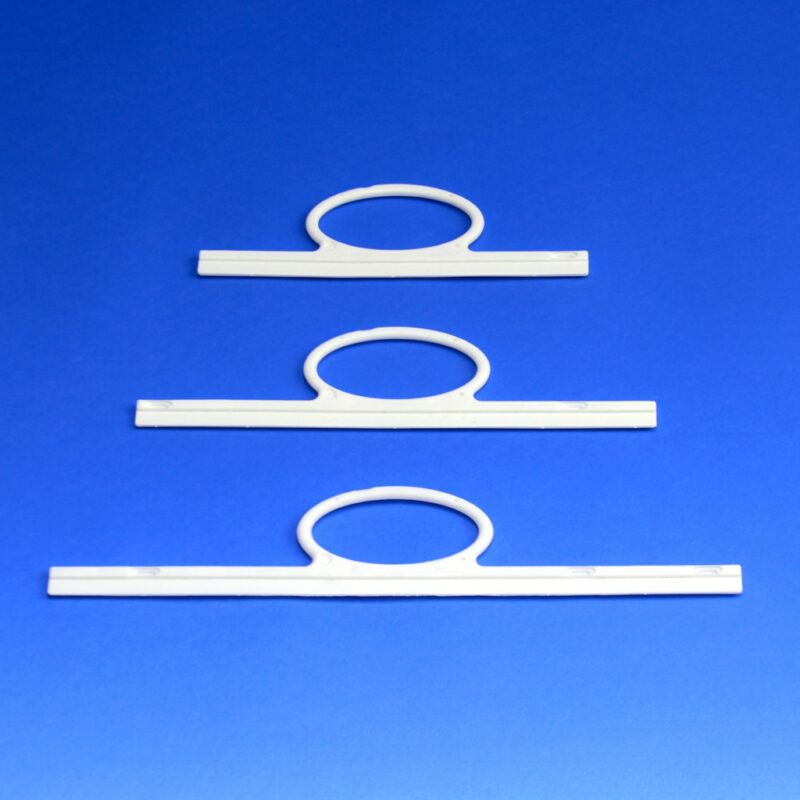

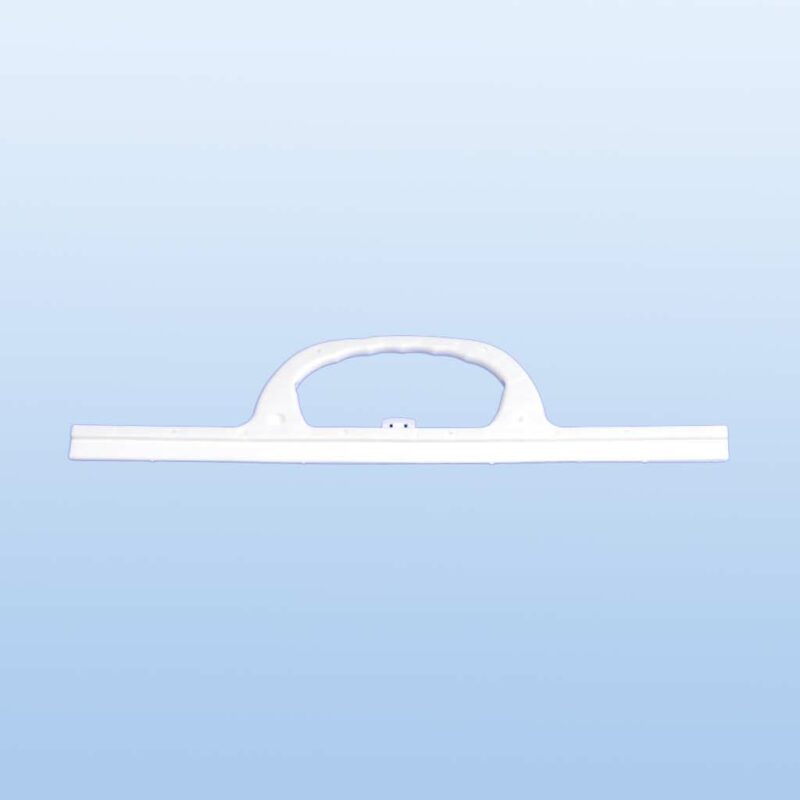

CLIP / ISO – twin handles – oval

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

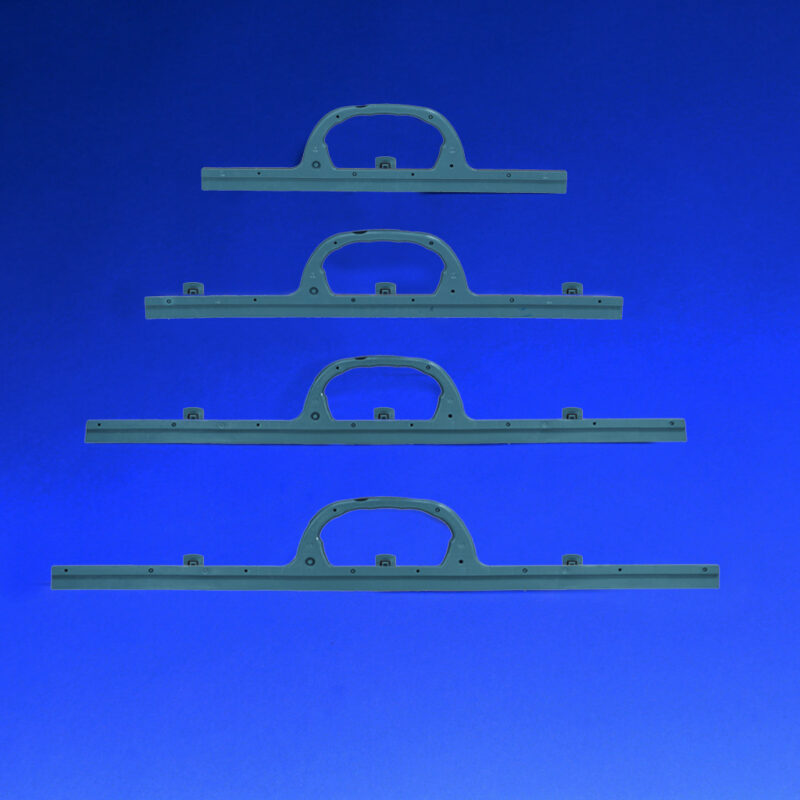

DTI / ISO – twin handles – oval PCR

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

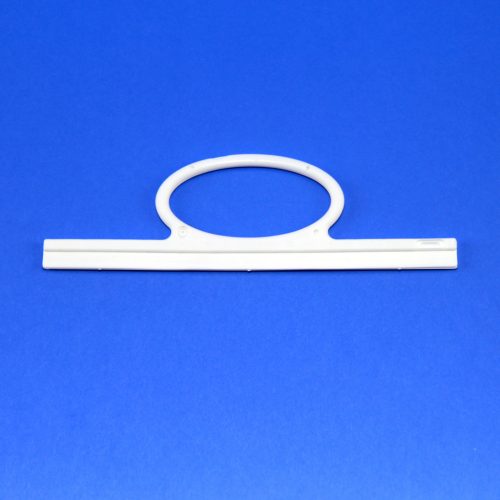

DTI / ISO – twin handles – oval

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

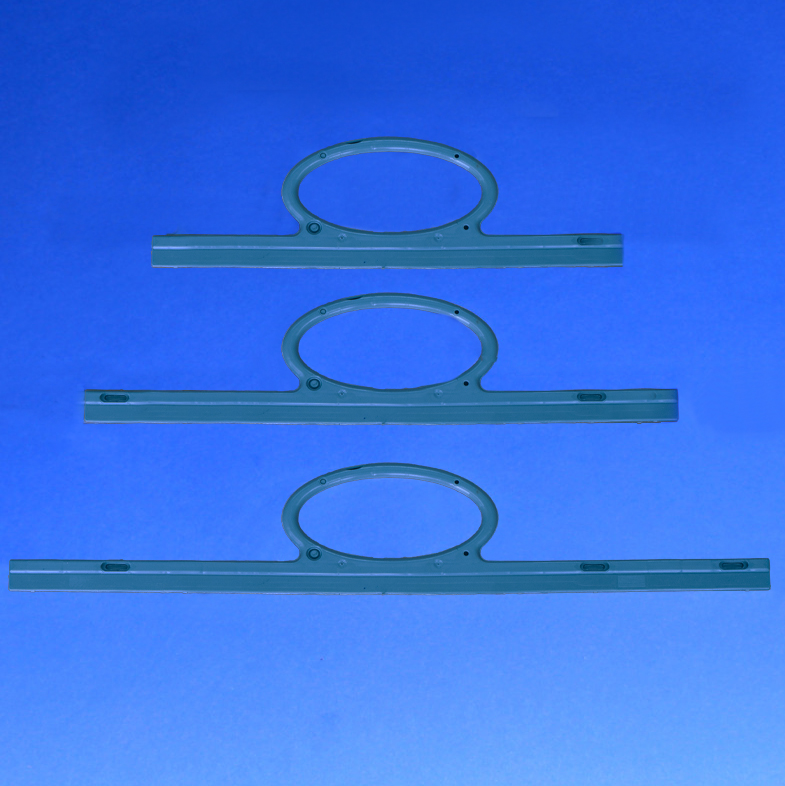

POG / Oval – twin handles – oval PCR

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

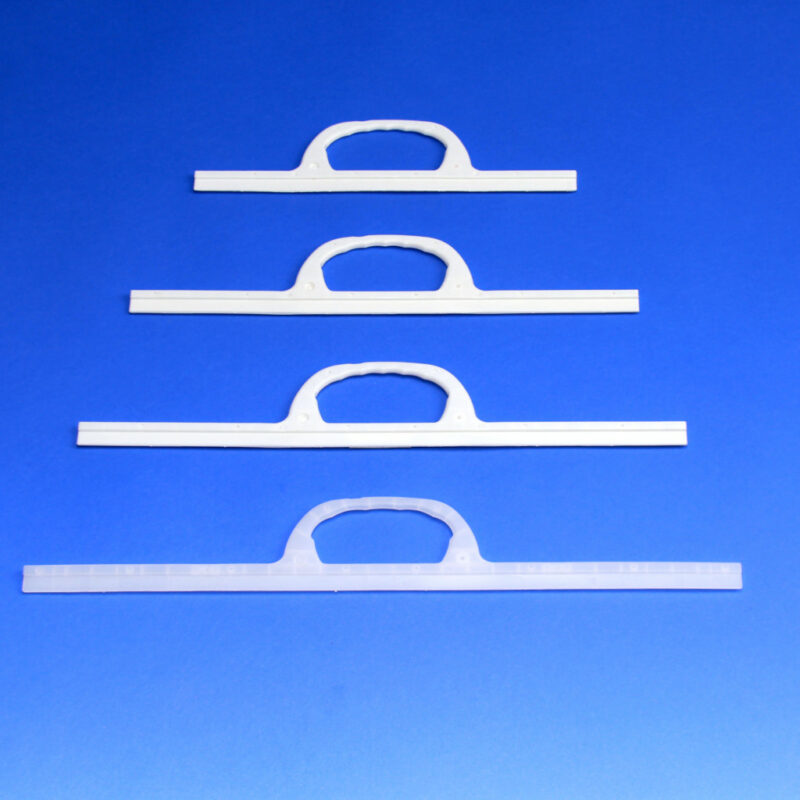

POG / Oval – twin handles – oval

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

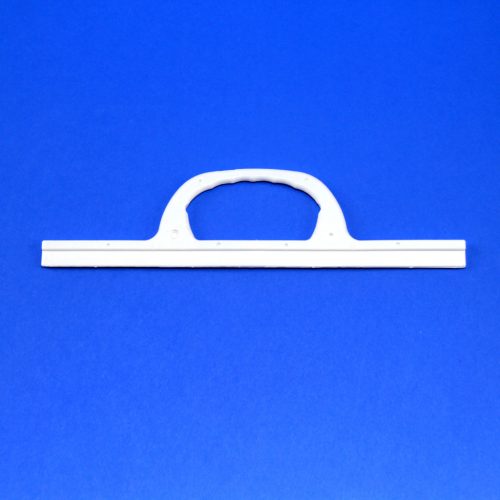

DTS / Trapez – twin handles – trapeze

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

DSV – Fruit bag handle – safety lock

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

EHH – single hook racks

Bitte verwenden Sie das Anfrageformular für weitere Informationen. -

WJL – grip tapes

Bitte verwenden Sie das Anfrageformular für weitere Informationen.